Japan has unveiled plans for an innovative “autoflow road” system that promises to transform cargo transportation between Tokyo and Osaka. This groundbreaking project, stretching approximately 320 miles, represents a significant leap forward in automated transportation infrastructure and offers a glimpse into the future of freight delivery.

Far from the simple conveyor belt system its nickname might suggest, the autoflow road is set to be a sophisticated network of autonomous robotic pallets operating around the clock. The project, overseen by Yuri Endo, a senior deputy director at Japan’s Ministry of Land, Infrastructure, Transport, and Tourism, aims to create dedicated spaces within existing road networks for automated, unmanned logistics operations.

The ambitious initiative comes in response to Japan’s critical shortage in delivery capacity, driven by recent regulations limiting overtime hours for truck drivers. Government projections paint a concerning picture: by the decade’s end, the country could face a 14 percent deficit in delivery capacity, potentially leaving a third of Japan’s cargo undelivered. The economic implications are severe, with estimated losses reaching $70 billion by 2030 alone.

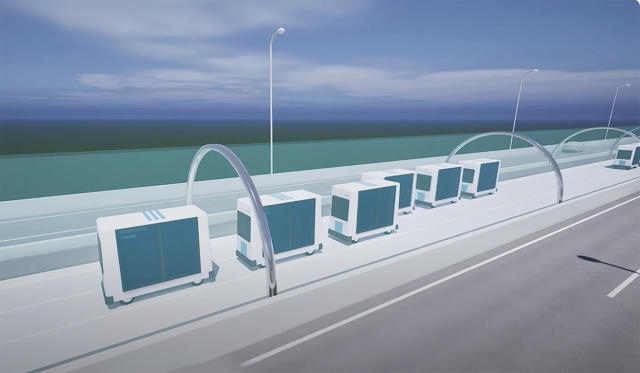

The design of the autoflow road system reflects careful consideration of efficiency and safety. The three-lane configuration includes a central lane serving dual purposes as both a passing lane and temporary stopping area, while the outer lanes accommodate opposing traffic flows. What sets this system apart is its sophisticated coordination capabilities, allowing autonomous pallets to form dynamic convoys and navigate between lanes with precision that would be impossible for human drivers to achieve.

At the heart of the system lies an intricate network of logistics bases where automated forklifts handle cargo loading and unloading operations. While the long-distance transportation will be fully autonomous, the final leg of delivery will still rely on human drivers for door-to-door service, creating a hybrid system that leverages the strengths of both automated and human-operated transport.

The scale of the project’s potential impact is remarkable, with the transport ministry estimating that this automated network could replace the work of approximately 25,000 truck drivers daily. This is particularly significant given Japan’s heavy reliance on road transport, which currently handles over 90 percent of the country’s cargo movement.

The investment required for this revolutionary infrastructure project is substantial, with estimates reaching beyond $24 billion according to Japanese newspaper Yomiuri Shimbun. The timeline reflects the project’s complexity, with initial testing scheduled for 2027 or 2028, and full operational capability not expected until the mid-2030s.

While some critics might view the autoflow road as an overly complex solution, Japan’s unique circumstances make such innovation necessary. The country faces a perfect storm of logistics challenges: an aging workforce, restrictions on working hours, and the inherent difficulty in attracting new drivers to what is often considered unglamorous and demanding work. Traditional solutions, such as simply hiring more drivers, appear increasingly unfeasible in Japan’s current social and economic climate.

The project represents more than just a solution to Japan’s immediate logistics challenges; it symbolizes the country’s continuing commitment to technological innovation in transportation infrastructure. Following in the footsteps of the iconic bullet train, which revolutionized passenger transport, the autoflow road system could set new global standards for automated freight movement.

As the world watches Japan’s latest transportation innovation unfold, the project raises intriguing questions about the future of logistics infrastructure globally. While some observers might question why traditional rail solutions aren’t being expanded instead, the flexibility and point-to-point capabilities of the autoflow system could offer advantages that traditional fixed-rail infrastructure cannot match.

The success of this ambitious project could have far-reaching implications for how other nations approach their own logistics challenges in an era of increasing automation and changing workforce dynamics. As Japan works to bring this vision to reality, it continues to position itself at the forefront of transportation innovation, potentially offering a blueprint for the future of freight movement worldwide.

Add Comment