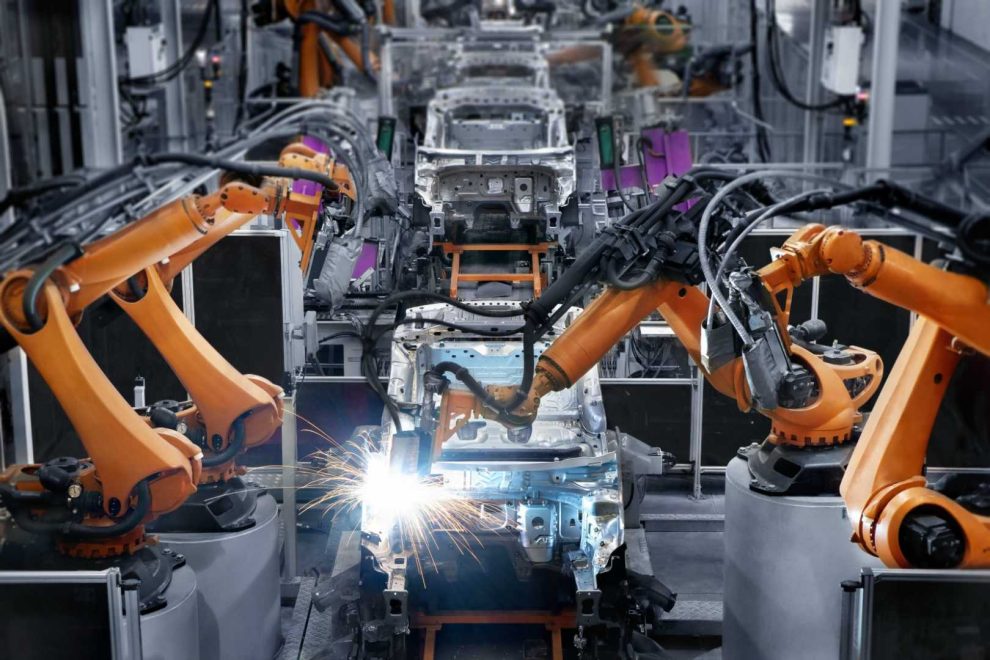

The image of a hulking metal arm tirelessly wielding a welding torch or meticulously assembling intricate components is no longer confined to science fiction. Industrial robots powered by artificial intelligence (AI) are rapidly transforming the factory floor, automating repetitive and dangerous tasks with unparalleled precision and efficiency.

From Simple Automation to Intelligent Companions

Traditional industrial robots, while adept at precise movements, lacked the adaptability and decision-making capabilities of their AI-powered counterparts. These newer robots, equipped with advanced sensors and sophisticated software, can now not only perform pre-programmed tasks but also react to their environment, make adjustments in real-time, and even collaborate with human workers.

Repetitive Tasks, Automated

One of the primary benefits of AI-powered robots is their ability to automate monotonous and physically demanding tasks. From welding, painting, and packaging to machine tending and quality control, these robots tirelessly handle the grunt work, freeing up human workers for more creative and strategic roles.

Safety First

Industrial environments can be inherently dangerous, with heavy machinery, hazardous materials, and potential accidents lurking around every corner. AI-powered robots can take on these dangerous tasks, minimizing the risk of human injury. Their advanced sensors and real-time analysis capabilities allow them to identify potential hazards and adjust their movements accordingly, ensuring a safer working environment for everyone.

Precision and Efficiency

AI-powered robots work with unerring accuracy and consistency, eliminating human error and significantly reducing production defects. Their ability to adapt to changing conditions and optimize their movements leads to increased efficiency and productivity, boosting overall output and profitability.

The Future of Work

The rise of AI-powered industrial robots raises concerns about job displacement. However, experts believe that these robots will not replace human workers entirely, but rather complement them. As robots take on the repetitive and dangerous tasks, human workers will be able to focus on higher-level skills such as design, engineering, and data analysis. This collaboration between humans and robots is expected to usher in a new era of intelligent manufacturing, characterized by increased productivity, innovation, and worker safety.

Challenges and Considerations

Despite the undeniable benefits, the integration of AI-powered robots into the workforce presents challenges. Issues such as the initial cost of implementation, the need for skilled personnel to operate and maintain these robots, and the potential for ethical concerns regarding workplace automation need to be carefully addressed.

The Bottom Line

In conclusion, AI-powered industrial robots are revolutionizing the manufacturing landscape. Their ability to automate repetitive and dangerous tasks, coupled with their precision, efficiency, and adaptability, make them invaluable assets on the factory floor. While challenges remain, the collaboration between humans and AI-powered robots holds immense promise for a safer, more productive, and innovative future of work.

Add Comment