Imagine a world where factories produce more with less, machines whisper their needs before breakdowns, and resource waste becomes a relic of the past. This isn’t science fiction; it’s the reality taking shape thanks to AI-powered predictive maintenance (PdM). By harnessing the power of artificial intelligence, industries are not only boosting efficiency and profitability but also contributing to a healthier planet.

The Problem: Industrial Hiccups with Environmental Hangovers

Traditional maintenance approaches, largely reactive and schedule-based, are riddled with inefficiencies. Unforeseen breakdowns lead to:

- Production halts: Idle machines consume unnecessary energy, releasing greenhouse gases into the atmosphere.

- Resource waste: Unplanned repairs often require replacing entire components instead of targeted fixes, leading to increased material consumption and disposal.

- Logistical woes: Emergency repairs disrupt supply chains, leading to additional transport emissions and resource use.

These issues combine to create a significant environmental burden. The International Energy Agency estimates that industry accounts for a staggering 70% of global energy-related CO2 emissions. Traditional maintenance practices exacerbate this problem, making the need for a sustainable solution critical.

Enter the Hero: AI, the Predictive Maintenance Powerhouse

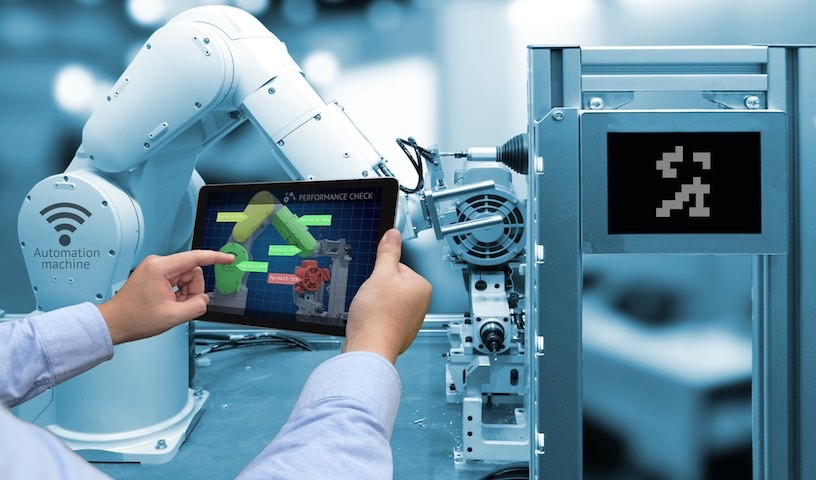

AI-powered PdM flips the script, transforming maintenance from reactive to predictive and preventative. Here’s how:

- Sensor symphony: Machines become instrumented with sensors that collect real-time data on vibration, temperature, power consumption, and other vital signs.

- AI analysis prowess: Advanced algorithms analyze this data, identifying subtle patterns and anomalies that indicate potential failures.

- Proactive interventions: Instead of waiting for breakdowns, AI alerts maintenance teams of impending issues, allowing them to schedule repairs during planned downtime.

This shift offers a plethora of environmental benefits:

- Reduced energy consumption: By addressing inefficiencies and preventing breakdowns, AI optimizes machine performance, leading to lower energy use and reduced emissions. Studies suggest PdM can cut energy consumption by up to 15%.

- Resource conservation: Targeted repairs based on specific needs minimize the need for complete component replacements, significantly reducing material consumption and waste generation.

- Optimized logistics: Planned maintenance schedules minimize disruptions and the need for emergency deliveries, leading to lower transport emissions and resource use.

Beyond the Numbers: Real-World Examples of Green Impact

The environmental benefits of AI-powered PdM aren’t theoretical; they’re already making a difference:

- GE Aviation uses AI to predict engine issues in airplanes, resulting in a 25% reduction in fuel consumption and CO2 emissions.

- Schneider Electric leverages AI for predictive maintenance in data centers, leading to a 30% decrease in energy use.

- Siemens implemented AI in wind turbine maintenance, achieving a 50% reduction in unplanned downtime and associated emissions.

These are just a few examples. As AI-powered PdM adoption grows, its positive impact on the environment will continue to expand.

The Road Ahead: Accelerating the Green Industrial Revolution

While AI-powered PdM offers immense potential, several challenges remain:

- Data infrastructure: Integrating sensors and building robust data infrastructure requires investment and expertise.

- AI expertise: The ability to develop and maintain AI models requires skilled professionals, creating a talent gap in some industries.

- Standardization: Lack of standardized data formats and communication protocols can hinder widespread adoption.

Addressing these challenges requires collaboration between industry leaders, policymakers, and research institutions. By promoting data sharing, investing in skills development, and establishing interoperable standards, we can accelerate the adoption of AI-powered PdM, paving the way for a greener and more efficient industrial future.

The Call to Green Action

The call to action is clear: embrace AI-powered predictive maintenance not just for business benefits, but for the health of our planet. By harnessing the power of AI, we can transform industries into responsible stewards of the environment, ensuring a more sustainable future for generations to come.

Add Comment